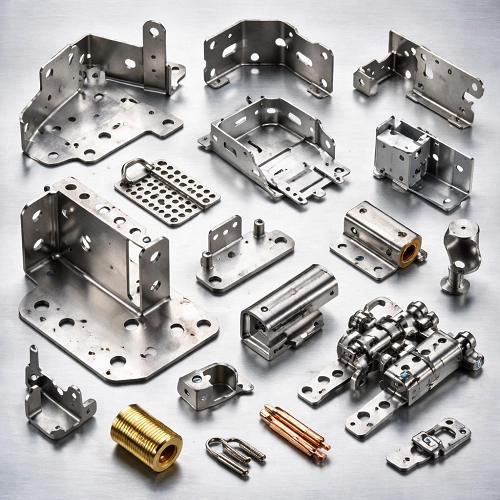

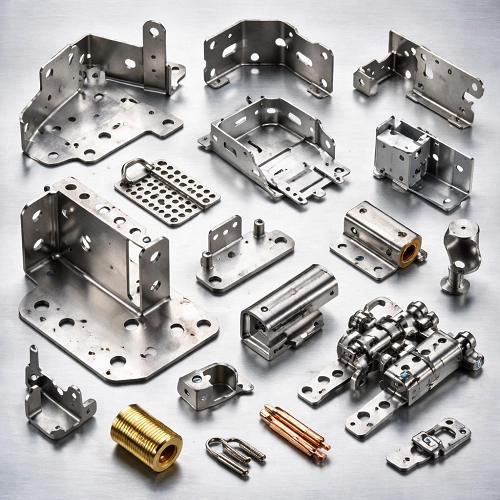

In modern manufacturing, precision and adaptability are crucial. Non-standard stamping parts are essential components that allow businesses to meet unique design requirements and maintain high-quality production. Unlike standard parts, which are mass-produced and uniform, non-standard stamping parts are customized to meet specific mechanical, structural, or aesthetic needs.

Product Functions and Uses

Non-standard stamping parts serve a variety of functions across multiple applications:

- Mechanical Components: They provide structural support, act as connectors, or facilitate motion in machinery.

- Electronic Devices: Used in the assembly of electronic housings, brackets, and connectors for various devices.

- Automotive Applications: Essential in car body structures, engine components, and interior fixtures, ensuring durability and precision.

- Industrial Equipment: Function as parts for conveyor systems, machinery frameworks, and other specialized equipment.

These parts are designed to handle specific tasks that standard parts cannot, ensuring that machinery and products perform optimally.

Product Features

Our non-standard stamping parts boast a range of features that make them ideal for specialized applications:

- High Precision: Manufactured using advanced stamping technology to achieve exact specifications.

- Durable Materials: Made from high-strength metals and alloys to withstand stress, wear, and environmental conditions.

- Customizable Design: Tailored to specific dimensions, shapes, and functional requirements.

- Surface Treatment Options: Available with coatings, plating, or heat treatment to enhance corrosion resistance and longevity.

- Lightweight Options: Designed for applications where reducing weight is critical without sacrificing strength.

These features ensure that our non-standard stamping parts meet rigorous quality standards and application requirements.

Product Specifications and Parameters

We offer a wide range of specifications to accommodate various needs:

- Material Types: Stainless steel, carbon steel, aluminum, copper alloys, and other specialized metals.

- Thickness Range: Typically 0.1 mm to 10 mm, depending on design and material.

- Dimensional Accuracy: Tolerances as precise as ±0.01 mm for critical applications.

- Shape and Size: Fully customizable based on client drawings or prototypes.

- Surface Finish: Options include polished, coated, anodized, or plated surfaces.

All specifications are fully adaptable to meet the precise requirements of different projects and industries.

Product Usage Instructions

To ensure optimal performance of non-standard stamping parts:

- Check Compatibility: Verify that the part design matches your machine or assembly requirements.

- Handle with Care: Avoid bending or deforming the part during installation.

- Clean Before Assembly: Remove dust or debris to maintain proper fit and function.

- Follow Installation Guidelines: Use recommended tools and techniques for assembly.

- Regular Maintenance: Inspect for wear or damage to prolong service life, especially in high-stress applications.

Following these instructions ensures reliability and safety in all applications.

Applicable Industries

Non-standard stamping parts are widely used across industries, including:

- Automotive Manufacturing: Engine components, chassis parts, brackets, and panels.

- Electronics: Housings, connectors, and structural frames.

- Machinery and Equipment: Custom components for industrial machinery and production lines.

- Aerospace: Lightweight and high-strength parts for structural and mechanical applications.

- Consumer Products: Precision metal parts for appliances, tools, and home devices.

Their versatility makes them indispensable in industries that demand precision, durability, and customization.

Target Customer Groups

Our non-standard stamping parts are designed for:

- OEM Manufacturers: Companies needing custom components for their products.

- Industrial Equipment Suppliers: Providers of machinery that require unique parts.

- Automotive Parts Manufacturers: Businesses seeking specialized components for vehicles.

- Electronics Assemblers: Companies producing devices with customized metal components.

- Aerospace and Defense Contractors: Organizations requiring high-performance precision parts.

We cater to clients who demand high-quality, reliable, and customizable solutions that meet their unique operational requirements.

Non-standard stamping parts are an essential solution for industries where precision, strength, and customization are non-negotiable. At ACRO Metal Products Ltd., we provide professional design, manufacturing, and support services to ensure your projects meet the highest standards of quality and performance.