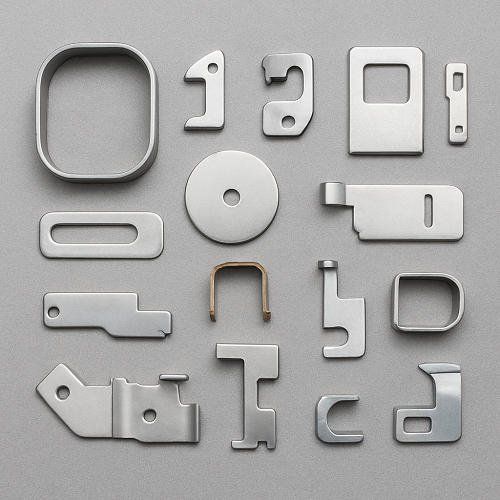

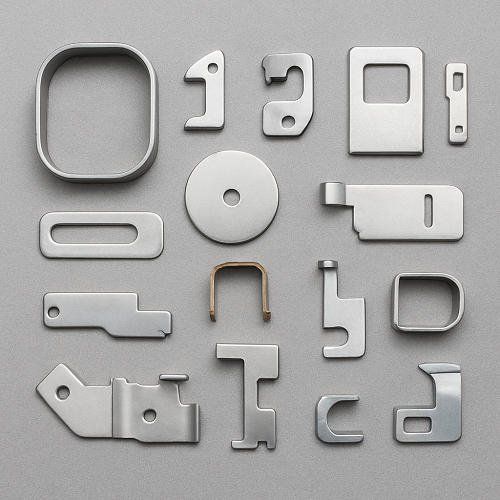

Metal stamping parts play a foundational role in today’s industrial supply chain, offering unmatched consistency, dimensional accuracy, and mass-production efficiency. As a company dedicated to high-quality metal processing solutions, we focus on delivering stamping components that meet strict performance standards, integrate seamlessly with different systems, and support long-term operational stability for our customers. Our metal stamping parts are engineered to optimize product functionality while keeping cost, durability, and manufacturability in balance.

1. Product Functions & Uses

Metal stamping parts serve as essential structural and functional components across numerous equipment assemblies.

Their primary functions include:

- Structural Support: Stamped parts are widely used as brackets, frames, housings, and reinforcement components. They provide strength and rigidity without adding unnecessary weight, making them suitable for compact and lightweight product designs.

- Electrical & Thermal Conduction: Copper, brass, and stainless steel stamping parts are used to create terminals, connectors, contact plates, and shielding covers. Their ability to maintain electrical and thermal stability ensures reliable performance in high-precision electronic devices.

- Fastening & Positioning: Precision stamping allows for the creation of clips, clamps, spacers, washers, and spring elements. These components ensure proper alignment, secure assembly, and vibration resistance within mechanical systems.

- Decorative & Protective Elements: Through surface treatments such as electroplating, anodizing, and powder coating, metal stamping parts can also serve aesthetic and protective purposes for high-end consumer products.

2. Product Features

Our metal stamping parts are characterized by several core features that define their performance and reliability:

- High Dimensional Precision: Using advanced CNC stamping equipment and progressive dies, we achieve tolerance control up to ±0.02 mm, ensuring perfect fit and compatibility with automated assembly lines.

- Strong Material Stability: We provide stamping solutions in various metals such as stainless steel, carbon steel, aluminum, brass, phosphor bronze, and beryllium copper. Each material is chosen based on application needs such as conductivity, elasticity, or corrosion resistance.

- Excellent Surface Quality: We apply a wide range of finishing options including deburring, polishing, plating, and anti-rust treatment to ensure smooth edges, enhanced appearance, and extended service life.

- Scalability for Mass Production: Our tooling and automated stamping systems are optimized for high-volume manufacturing, enabling short cycle times, consistent quality output, and competitive pricing.

- Customizability: We offer full customization services, from concept design and prototyping to mould fabrication and mass production. Our engineering team works closely with clients to ensure the stamped parts match their specific technical and operational requirements.

3. Product Specifications

We provide metal stamping parts in multiple standard and customized specifications:

Material Options

- Stainless steel (SS304 / SS316 / SUS430)

- Carbon steel (SPCC / SGCC)

- Aluminum (AL1050 / AL5052 / AL6061)

- Copper, brass, phosphor bronze

- High-elasticity alloys for spring clips

Thickness Range

- 0.1 mm – 6.0 mm depending on part design and required strength

Dimensions

- Customizable according to drawings, with support for micro-stamping and large-format stamping

Tolerance

- Typical: ±0.05 mm

- Precision applications: ±0.02 mm or tighter

Surface Treatments

- Zinc, nickel, chrome plating

- Black oxide, anodizing

- Electropolishing

- Passivation for stainless steel

- Powder coating or custom finishes

4. Product Instructions for Use

To ensure optimal performance of our metal stamping parts, we recommend the following usage guidelines:

Installation

- Verify dimensions and orientation before assembly to avoid deformation.

- Use proper torque or fastening methods appropriate for the material type.

- For electrical components, ensure clean contact points to maintain conductivity.

Storage

- Store in dry, dust-free environments.

- Avoid exposure to corrosive chemicals or moisture prior to installation.

- Keep finished components separated to prevent scratches.

Handling

- Avoid excessive bending or twisting of thin or spring-type stampings.

- Use anti-static packaging for sensitive electronic parts.

Maintenance

- For parts exposed to high-stress environments, periodic inspection is recommended.

- Surface-treated components should be protected from harsh abrasion to maintain coating integrity.

5. Applicable Industries

Our metal stamping parts are widely used across multiple industries, including but not limited to:

- Automotive & Transportation: Door mechanisms, electrical terminals, sensor housings, brackets, and chassis components.

- Consumer Electronics: Battery contacts, shielding covers, connectors, camera parts, laptop hinges, and speaker frames.

- Industrial Machinery: Mounting plates, clamps, spacers, housings, and structural supports.

- Home Appliances: Reinforcement plates, metal frames, switches, cooling system components.

- Telecommunications: Signal connectors, RF shielding covers, grounding elements.

- Energy & Power Equipment: Terminal blocks, conductive plates, battery system components.

6. Target Customers

Our metal stamping parts are designed to serve a wide range of clients, including:

- Manufacturers of Electronics and Appliances: Companies requiring high-precision, high-volume stamped components for consumer and industrial products.

- Automotive OEMs and Tier Suppliers: Customers needing durable, dimensionally stable parts for vehicles, EV systems, sensors, and mechanical assemblies.

- Industrial Equipment Producers: Firms seeking reliable metal structural and functional parts for machinery and production systems.

- Engineering & R&D Departments: Teams needing rapid prototyping, customized tooling, or material optimization for new product development.

- Global Distributors & Component Integrators: Organizations sourcing standardized or custom-made metal parts for diverse downstream applications.